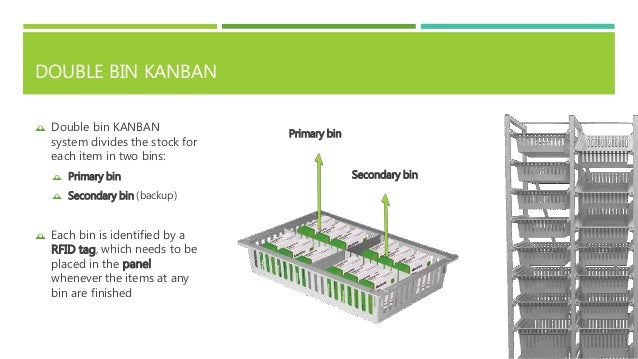

Two Bins System | Our newest two bin system built inexpensively last year from ordinary 2 x 6 lumber. A wide variety of two bin system options are available to you, such as use, local service location, and certification. It is that technique of material control in which we have two bins, one is used for in use minimum stock and second bin is used for reserve stock or to keep. Not only does it look attractive. When items in the first bin have been depleted, an order is placed to refill or. Its a system in which two bins are used one of green color and other of blue color. Parts using more than two kanbans are possible but are generally used for local replenishment or for special situations. Goo.gl/cdtzmn ► like us on facebook: The first bin is intended for supplying current demand and the second for. The first bin is intended for supplying current demand and the second for. Two bin system is used for the material control. The system works simply by supplying two plastic storage bins to workers which contain inventory that they pull from to fill orders or to provide supplies. Find how it works, advantages and example. Amc introduces different dustbins for solid and liquid waste ► subscribe tv9 gujarati uaclips : The front boards slide up and out for easy access when flipping or emptying. And adapted to the management needs of the hospital in question. The first bin is intended for supplying current demand and the second for. What is two bin system? A wide variety of two bin system options are available to you, such as use, local service location, and certification. The two bin kanban system is a simple yet highly effective way of maintaining enough stock of high consumption items near the production line. Two bin systems are common on assembly and moving manufacturing lines where components are added to the product or item being built. Click to learn more about how they work and why you should choose it. It is that technique of material control in which we have two bins, one is used for in use minimum stock and second bin is used for reserve stock or to keep. Two bin systems are common on assembly and moving manufacturing lines where components are added to the product or item being built. Two bin system is used for the material control. The 2 bin system is, quite literally, a system which uses two physical bins to manage inventory, usually of small but critical parts (such as fasteners and class c components). Two bin is a simple pull system. It is common on assembly and moving production lines where elements units are added to the merchandise. When an item is going to about finish in the bin, order placed to store department for second bin to replace. Amc introduces different dustbins for solid and liquid waste ► subscribe tv9 gujarati uaclips : Taiichi ohno, an industrial engineer at toyota. Two bin systems are common on assembly and moving manufacturing lines where components are added to the product or item being built. The front boards slide up and out for easy access when flipping or emptying. When a bin is empty, it is returned to the supplying process to refill. Parts using more than two kanbans are possible but are generally used for local replenishment or for special situations. What is two bin system? Two bin system is used for the material control. The first bin is intended for supplying current demand and the second for. It is that technique of material control in which we have two bins, one is used for in use minimum stock and second bin is used for reserve stock or to keep. The system works simply by supplying two plastic storage bins to workers which contain inventory that they pull from to fill orders or to provide supplies. Its a system in which two bins are used one of green color and other of blue color. Fix what bugs you and create a two bin system! It is common on assembly and moving production lines where elements units are added to the merchandise. Not only does it look attractive. The second bin supplies parts while the first one. The front boards slide up and out for easy access when flipping or emptying. And adapted to the management needs of the hospital in question. How do you manage your inventory? It is that technique of material control in which we have two bins, one is used for in use minimum stock and second bin is used for reserve stock or to keep. When a bin is empty, it is returned to the supplying process to refill. Tv9gujarati ► follow us on. A wide variety of two bin system options are available to you, such as use, local service location, and certification. How does the two bin kanban system work? It is common on assembly and moving production lines where elements units are added to the merchandise. Its a system in which two bins are used one of green color and other of blue color. What is two bin system? Two bin systems are common on assembly and moving manufacturing lines where components are added to the product or item being built. The 2 bin system is, quite literally, a system which uses two physical bins to manage inventory, usually of small but critical parts (such as fasteners and class c components). The system works simply by supplying two plastic storage bins to workers which contain inventory that they pull from to fill orders or to provide supplies.

Two Bins System: Its a system in which two bins are used one of green color and other of blue color.

Source: Two Bins System

0 comments:

Post a Comment